Plasma Electrolytic Polishing with a Jet

- Degree programme: Master of Science in Engineering

- Author: Yan Scholl

- Thesis advisor: Prof. Dr. Cédric Bessire

- Expert: Dr. Christof Bernhard

- Year: 2024

Plasma electrolytic polishing is an innovative polishing technique that uses environmentally friendly salt water-based electrolytes to achieve better polishing results than traditional methods like electropolishing (EP). This thesis is about the concept of a novel machine for plasma electrolytic polishing with a jet (PEP-Jet) and the investigation of the possibilities of PEP-Jet.

Introduction

Polishing metals is a crucial process across various industries. It helps to increase wear and corrosion resistance, decrease surface adhesion, and enhance biocompatibility and gloss. Today, the state-of-the-art surface finishing technique is electropolishing (EP), which requires toxic and harmful electrolytes.

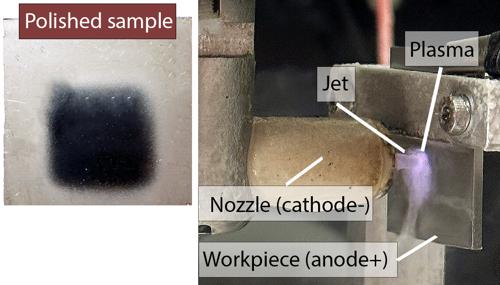

Plasma electrolytic polishing (PEP) is a new ecological polishing method that uses aqueous electrolytes and enables the polishing process to be used in a jet configuration (PEP-Jet). The PEP-Jet enables the polishing of workpieces locally and even within workpiece cavities. This new PEP-jet solution allows the polishing of workpieces partially or in areas impossible with EP.

Objectives

This master thesis has three main objectives:

(1) Development of a concept for an industrial PEP-Jet machine; (2) Study and improve the polishing results of PEP-Jet in terms of homogeneity of the surface and the preservation of contours of workpieces; (3) Expanding the material range for PEP-Jet with different metals relevant in various high-end surface industries.

Results

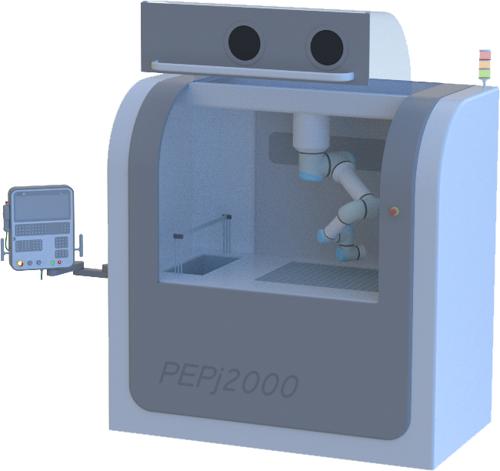

The concept for an industrial PEP-Jet machine provides a base configuration of a machine with a manually operated jet for simple and affordable integration into current productions. It is based on customer needs from various industries that could profit from this technology and insights from previous projects. The base configuration can be expanded with automated PEP-Jet polishing using a robot or cobot. Depending on the applications, the machine can be equipped with different power options and a PEP bath.

Tests with different polishing patterns and multiple jets in different jet arrangements provided valuable insights and improved the homogeneity of the polishing area using PEP-Jet. An optimal method for maintaining workpiece contours was successfully implemented through specific approaches on the workpiece edges using the PEP-Jet.

The PEP-Jet polishing was successfully performed on different materials, including copper, various carbon and stainless steels, and even titanium and cobalt alloys. The achieved surface finishings met the hygienic standards required in medical applications.